Hybrid Chuck

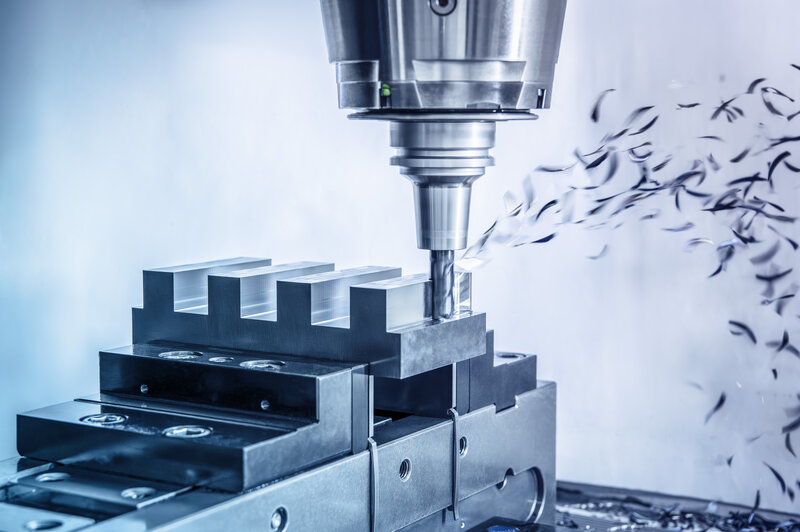

Pioneering technology in the field of tool holding

The HAIMER Hybrid Chuck enables higher vibration dampening than conventional shrink fit chucks thanks to the innovative type of tool holding, but retains the high clamping forces and perfect runout accuracy that characterize a typical shrink fit chuck.

Highlights

- Increased tool life and minimized production times thanks to vibration damping

- Particularly suitable for high-performance cutting (HPC) and high-speed machining (HSC)

- Ideal for use with materials that are difficult to machine

- With the following upgrade options: Cool Jet, Safe-Lock

Top-class shrink Fit chuck

Special features

Technical specifications

Machining parameters

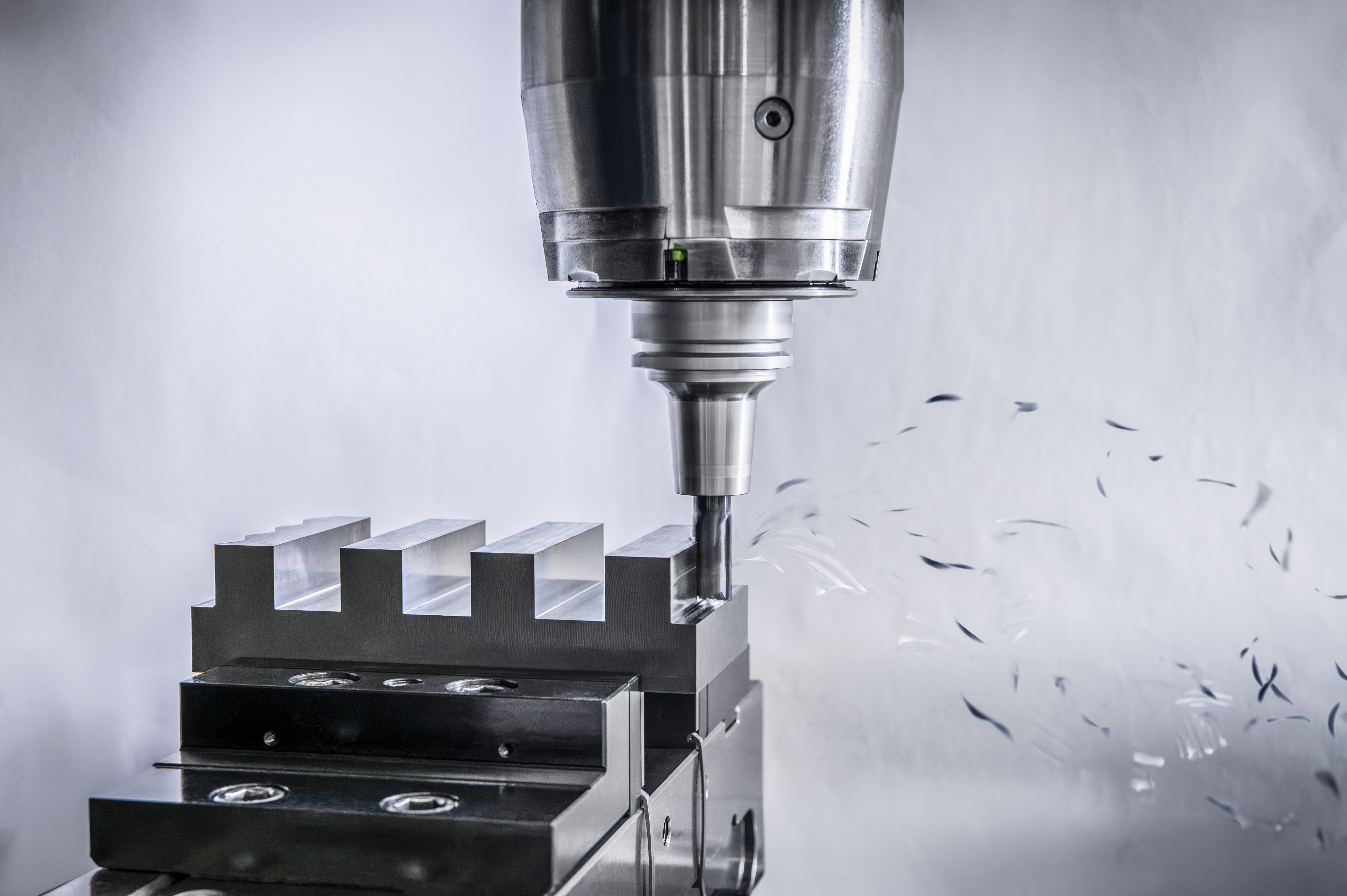

- Machine: DMG MORI DMC 1035V

- Interface: HSK-A63

- Material: 42CrMo4

- Tool: HAIMER MILL Power Series Z4 (F1004NNL1600CAA)

- Cutting speed: 120 m/min

- Feed per tooth: 0.09 mm

Return stroke

- Heavy Duty Shrink Chuck: 1,375 mm/min | Feed per tooth: 0.14 mm

- Hybrid Chuck: 1,718 mm/min | Feed per tooth: 0.18 mm

Surface finish & material removal rate

- Standard Shrink Chuck: Rz 13.00 | 72 cm³/min

- Power Shrink Chuck: Rz 3.63 | 164 cm³/min

→ +125 % productivity vs. Standard Shrink Chuck - Heavy Duty Shrink Chuck: Rz 2.19 | 297 cm³/min

- Hybrid Chuck: Rz 1.89 | 367 cm³/min

→ +123 % productivity vs. Power Shrink Chuck

→ +23 % productivity vs. Heavy Duty Shrink Chuck

HAIMER TOOL HOLDER OVERVIEW

HAIMER offers the right toolholder and clamping technology for every application, from high-speed machining to heavy-duty machining. Continuous investment in research and development results in innovative and reliable solutions that ensure our customers a sustainable competitive advantage.

This might also interest you

Power Clamp Premium i4.0

Ergonomic high-end shrink station in premium quality industry design with integrated contact cooling.

Coolant tubes

Ensures precise coolant supply, improves chip evacuation, and extends tool life.

Toolbase EL-9 Professional dispensing cabinet

Dispensing cabinet or an alternative control unit for complex systems.

Panther MILL

Absolute all-rounder for side milling and slotting in all steel and stainless materials.